Marybeth Bullington in Creswell, Oregon

Marybeth contacted us recently to suggest that we interview a friend of hers who is a great cheese maker. We could see from the link she gave us that the other cheese maker is probably indeed a great cheese maker, and we hope to interview him soon.

But, we wondered if Marybeth herself might be worthy of an interview. After all, she had told us she makes cheese.

Fortunately, she acquiesced to our request. Now, we’ll let you decide if you agree with us that she is, indeed, very much worthy of our attention …

Marybeth’s Story

Our household consists of my husband, two dogs and one very large cat. Outside the house are chickens (the cleanup crew for unworthy cheese experiments) and 50 +/- goats.

Our farm – Elfin Acres Nigerian Dwarf Goats is 13 miles south of Eugene.

I am retired from a lifetime affliction of working in unofficial ‘forensic accounting.’ My final ‘real job’ for over a decade was working for a global clothing company’s inventory control.

All industries are changing at light speed as they seek new ways of doing business. My task evolved into monitoring new innovations for glitches. I refer to it as ‘affliction’ as my heart was in the barn, but the ‘real job’ paid the bills.

I used to raise registered Shetland sheep. Lots of them!

I love the heritage breeds and it was important to me to promote and protect the landrace qualities of the Shetland. They are the Einsteins of the sheep world – not selectively bred to be ‘stupid.’ (Silky soft fleeces in fabulous colors, too.)

Then, at a sheep show I met a couple of baby Nigerian Dwarf dairy goats!

The owners brought the bottle babies as they needed multiple feedings throughout the day.

Smitten was an understatement. Soon the sheep herd was dispersed to others with high regard for their heritage qualities. And now we have barns* full of little goats!

*We have a Buck Barn, Chicken Palace, the Doe Barn 24 x 36, and the East Side Barn which is an addition. That part is 14 x 60 and separated into our hay storage area, the ‘Diet Spa’ (for does in need of slimming), Sorority (for young does) and an overflow lounge for the main Doe Barn.

Every month we weigh and sample the doe’s production for two milkings, 12 hours apart. This tells us not only how hard they are working but what the butterfat % is, protein and anticipated cheese yield (based on cow production, I use it to boost the doe’s egos since their yield far outshines the cows) and somatic cell count to monitor udder health.

In the fall, something wonderful happens with the milk as the girls progress farther into their lactation. The volume of milk starts to gradually decrease but the butterfat produced stays about the same. That means the butterfat percentage starts to rise, sometimes dramatically.

This is especially true of the Nigerian Dwarf milk. The September herd average is 6.73% butterfat. By December, it could be as high as 11 or 12% on average. Yes! I do make goat butter and it is delicious!

The baby goat looks much bigger in this than he really is. Trying to juggle baby goat, bottle and phone was dicey!

Cheese came shortly after the goats arrived on the scene. I hadn’t really intended to start milking, but one sip of the Nigerian Dwarf goat milk and I was hooked. Now I milk 20 to 26 goats twice a day and make cheese whenever time allows.

I love everything cheese, especially the goats that make it possible.

How I learned to make cheese …

Not surprisingly, I started with Ricki Carroll’s Home Cheese Making. My copy is well trained to flop open at favorite recipes with notes in the margins and appropriate whey stains. The book collection has grown; you never know when someone will come up with a new twist on an old favorite.

I took one class from a goat mentor, Gianaclis Caldwell early on. I love her books which explain the science behind the actions needed to get a specific result in the cheese.

I use your Dutch Style Cheese Press which works very well for me. I do get some teasing about the things I hang on the weight arm to get just the right pressure.

The alchemy of changing fluid milk into wildly disparate flavors and textures fascinates me. From mild and creamy chevre to the intense gritty grana of an aged parmesan style cheese, it’s all possible with a few little tweaks in the process.

Harry Potter may have his wand but I have my cheese books and hardworking dairy goats!

My cheese …

I think my first cheese was paneer. I still remember the absolute magic of watching milk morph into cheese.

A staple at the farm is Greek style yogurt. The Instant Pot has a 1 ½ gallon batch every week. The drained whey from yogurt and cheese making is a welcome treat for “the girls.”

For draining a big batch of curds, I use a cloth lined non-stick grill basket I keep for just that purpose. It has no ‘blind spots’ to hinder good drainage.

Spring and summer I make chevre with fresh, still warm, raw milk. So easy and delicious! In fall, when the butterfat in late lactation can average 10 to 13%, the Camemberts and Valençay take center stage.

I usually make 4 gallon batches of cheese at a time. It takes just as long to make a 1 gallon batch as a big batch! Friends, extended family, milk customers, neighbors are all recipients of successful cheese ventures.

One of my favorite experiments was with Stilton. I named my cheese “Pilfered Bleu.” I was not happy with the results of the bleu molds I had acquired. They succeeded but I wanted a specific Stilton flavor profile.

I snagged a tiny wedge of expensive Stilton and crumbled it into some nicely warmed fresh raw milk from my herd. I did consume some of the cheese of course, (constant quality control is required). Then, I used that as a starter with some additional culture to get things rolling.

It was unbelievably ugly and absolutely scrumptious! A few chosen cheesaphiles and I spent happy moments harvesting the unattractive exterior onto crackers or bread and then replacing the block into the wine cooler ‘cave’ to renew its moldy self for another culinary adventure.

A take away from my experiments with bleu cheese was that once an affinage space has experienced the joy of bleu mold, you will enjoy it forever in that space no matter your intentions for the current residents.

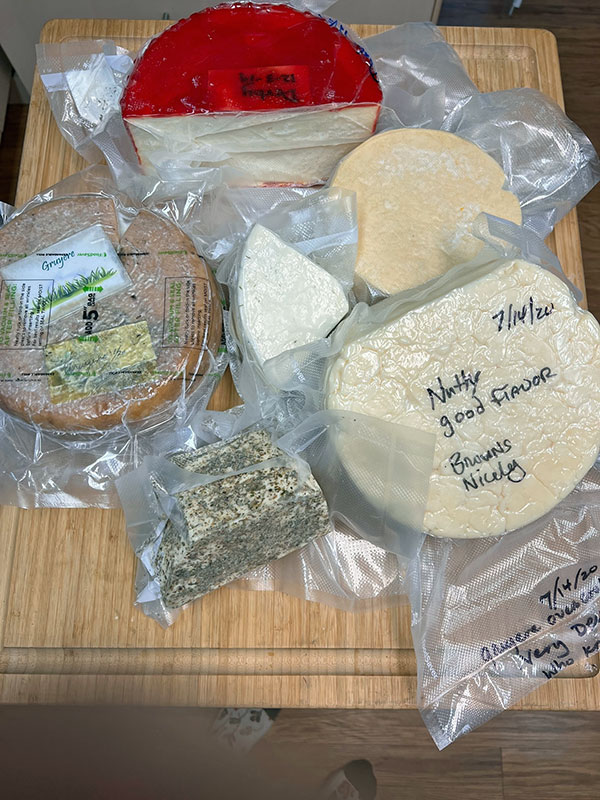

Clockwise from the top is a Derby, Manchego (unlabeled on this side), Gruyere, herb crusted hunk of aged farm cheese, and a 2 year old olive oil rubbed Gruyere, cave aged for a year then vacuum sealed. (One can only consume so much cheese in lockdown!) Center is the Dill Caerphilly.

Labeling and storing …

To keep track of what is going on, I write directly on the vat at the first stage of the make (I use a sharpie on the lid. Scrubs right off!). Then, I transfer the info to a piece of freezer tape until I get to the aging stage.

Once the pressed cheese has been salted and dried, I usually vacuum seal it. I write the pertinent details on the bag.

Usually, I will cut the bag a bit long since I will re-seal the wheel of cheese a number of times before it is gone. For soft cheese, the freezer tape does nicely on the ageing container. Extra notes are added as needed.

I do love the vacuum sealing. It is great to cut a few wedges and reseal it to avoid eating the whole wheel. (Once opened, I do tend to nibble away well beyond the required quality control check.)

I keep the vacuum sealed cheese in long sleeps in the warmer veggie bins in the 36F milk storage fridge.

Some are now several years old as the intended family gatherings have been on hold. Holidays are coming and maybe this year we can present the family with a cheese board of magnificent variety. Of course not everyone ages gracefully. The chickens are thrilled with those in the ‘Meh!’ category.

Challenges …

There are three major challenges to my cheese making.

· Not enough time,

· Way too much beautiful rich milk, and

· Making more cheese than my tolerant husband, friends and extended family can consume.

Not enough time:

Farm folks NEVER have enough time. I recently retired from a 40 hr/week job. One would think that would free up lot of time for other endeavors like cheese making. However, farm work/animal care/garden maintenance is like housework. It takes up the amount of time one has available. (Remember how fast you can clean a house when unexpected company is on the way “just passing through?”)

Way too much beautiful rich milk:

This is truly a dairy person’s self made guilt trip. What do you do with excess milk? Sometimes customers go on vacation or the does are working their little hoofies off to fill the bucket.

I have been known to make chevre in a stainless steel pail right after the milk is filtered because there is no room in the milk fridge (kept at 36F).

Every goat keeper will have this dilemma at some time. This is what often prompts the above situation to be shifted to “Make Time” for cheese making.

One does tend to look at cheese recipes that use a LOT of milk with the fewest fussy details to get to the end of the process. Think chevre – milk goat, strain milk, add culture and a drop or two of rennet, cover and leave on counter over night. Drain chevre, add salt, mix it up, flavor it if desired,* package it and either sell or give it to loyal milk customers. And just like that, you can consolidate 4 gallons of milk.

*Have you ever tried chocolate chevre? I mix a good quality cocoa powder, liquid Stevia, and chocolate shavings into my chevre. (I use stevia because I am intolerant of sugar.) When one is on a Keto-friendly regimen, this is like a scoop of rich chocolate ice cream without the guilt or ice!

Making more cheese than my family can consume:

This is when the delivery guy, the feed store people, and the occasional farm visitors unexpectedly go home with cheese.

Being a cheesemaker with lots of goat milk is a blessing in that one never has to buy presents. All friends and relatives know they are getting cheese, the only variable is what kind.

My philosophy …

I am 180 degrees from some others I know in my approach to cheese making. They are very precise in the cheese making process. I, on the other hand, work from the basis that cheese came about by a happy accident eons ago and the different varieties were created by what worked for the intrepid cheesemakers in their specific environments.

In other words, Serendipity is a large part of my methodology. Timing, temperature and additions are governed by what’s happening on the farm. (The cell phone alarm goes off to add the rennet. Oops, can’t do it now, delivering baby goats.) Most of the time the results are delicious but somewhat askew from the intended character. In case of abject failure-there are happy chickens.

Marybeth Bullington

Elfin Acres Nigerian Dwarf Goats

http://elfin.acres.com

mbsheepmom@gmail.com

(541) 914-6240

(541) 895-2119

Facebook: https://www.facebook.com/marybeth.bullington.9